Product/Process Engineering

We provide a product engineering service, supporting the customer from the development phase of the project to its realization.

Through a team of experts, we are able to study and propose technical solutions aimed to improve the product itself in terms of manufacturability, cost reduction and increased reliability, while remaining faithful to the technical specifications defined by the customer.

We also design and optimize the production cycle, considering not only the project specifications but also the available manufacturing technologies and internal know-how, so that the product can be manufactured efficiently and effectively.

Procurement

The company offers a procurement service for all parts of the product starting from PCBs, components, wiring, plastics, mechanical parts up to packaging, operating both on the Italian and international markets, through the continuous search for excellence’s suppliers.

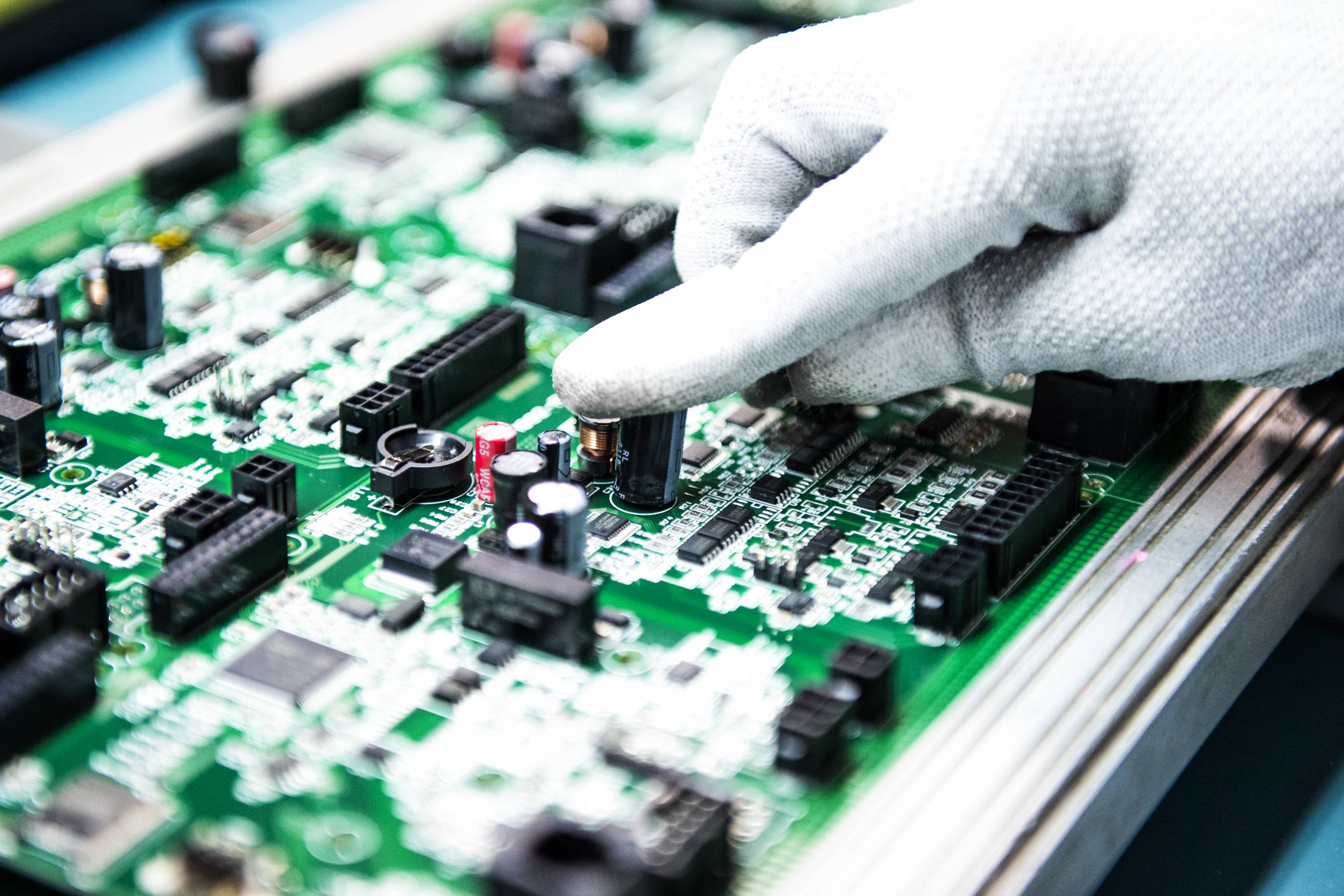

SMT Assembly

Our core business is the assembly of electronic boards in SMT technology. Every year we invest in top-of-the-line equipment on the market, providing high-performance production lines.

The assembly lines are capable of assembling BGA, Ultra-fine Pitch, LGA, QFN components and are also versatile for mounting on different types of substrate.

Each phase of the SMT welding process is monitored and validated by means of control instruments, starting from the 3D Solder Paste Inspection, which verifies the correct deposition of the solder paste, to the 3D Automatic Optical Inspection, which ensures the quality of the welds and the correct positioning of the components.

Finally, the 3D X-RAY inspection allows to check the solderability of non-visible pins on a samples or on 100% of the production.

BGA and micro-BGA rework can be performed on the offline station at the end of the SMT assembly process.

To protect the lines from sudden power cuts and guarantee production continuity, we have set up some uninterruptible power supplies.

THT Assembly

The traditional THT assembly includes the preforming service of the electronic components, the component assembly phase and the wave soldering of the boards.

Manual welding is carried out where necessary by our team of experienced technicians certified to IPC standards.

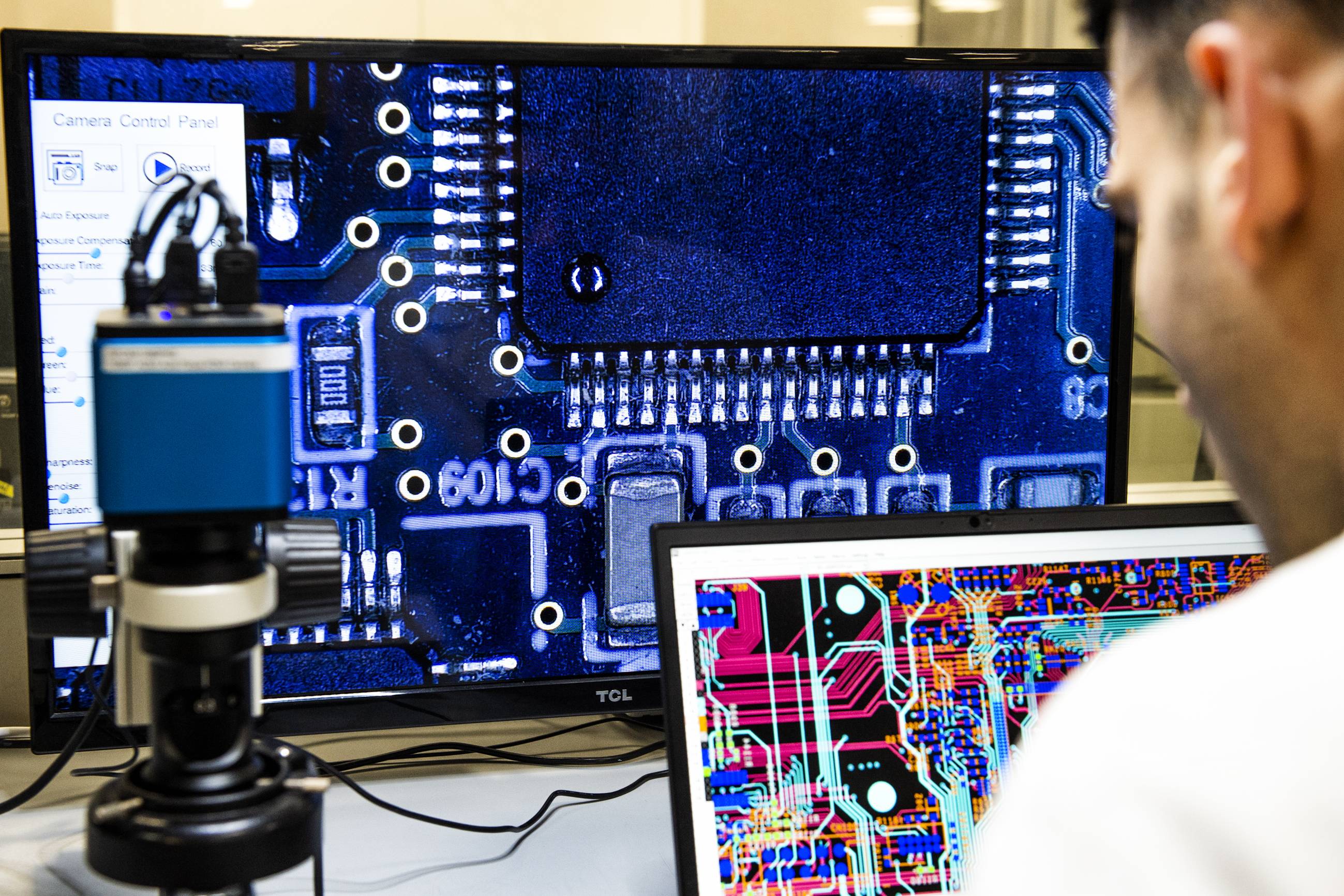

Testing

The manufacturing of an electronic board ends with testing process, to ensure its correct functioning and to evaluate the behavior and performance capacity of the board itself.

Thanks to the specific testing services offered, we are able to cope with various control and programming requests, from ICT test on Flying Probes and/or Bed of Nails, to functional test.

Our team of experts guarantees support from the project to the realization of the dedicated test bench.

Finished Product Assembly

We are able to offer specific processes such as: mechanical assembly, resin coating, wiring and packaging of all kinds, with solutions that respect antistatic.

We have adopted the concept of "Global Service" or rather the customer has the possibility to request a "turnkey" product, complete in all its parts and ready for the end user.

Customer Care

Service department is a fundamental element in our organization.

Through a team of experts, we are ready to face and welcome customer requests and act in the shortest possible time.